CMF_k11_facelift

» CMF MemberHello, this is my first blog as such, on here.

It's a 1 litre facelift. I focused on aesthetics the first year I owned it, lowered on coilovers and put it on 13x7 re-drilled Ford Capri Brooklands.

I managed to get the 0-60mph in about 10seconds from the 1.0 with cg13 cams and a ga16 airbox, but daily driving was still sluggish, hence why I'm now turbocharging it.

Now sporting some widened steelies:

And raised it a fair bit for a more subtle look:

The turbo is a Garret T2 from a Fiesta RS. And the manifold's built by Frank. I've been putting it together and mocking it up on a spare cg13 which will replace the 1.0 when I get time or get bored. I've got oil lines and sump almost done, throttle body and MAF are in the making.

The plan is, to be honest, very similar to franks ghetto build. For me it's a learning experience working with turbos on a budget. I also rate these 1.0 litres, so it would be fun to see what they can do. I won't be chasing figures, just experimenting and having fun too.

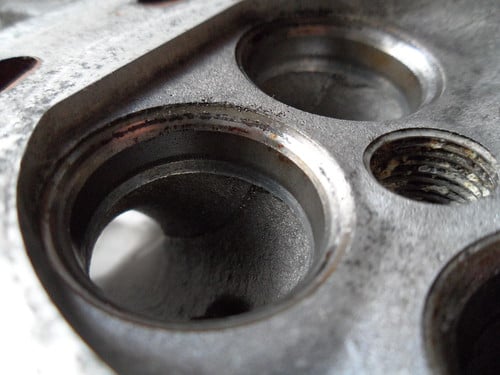

The head was completely stripped and cleaned. Widened and polished the ports myself, matched the inlet manifold and the gasket. Have also added additional valve spring washers to increase the valve spring rates, so I should be good for 8000rpm+ if I ever needed to go that high.

Before:

after:

I'm unsure whether to raise or lower the compression ratio on it though. These turbos are usually good for upto 1bar of pressure. Any more than that and they're prone to splitting seals quite early. I'll probably work it up to 10psi in time. However I'm unsure if lowering the c/r to the typical 8.5:1 will see the best increase in power and torque due to the low boost. I could raise it to 10.5:1 to hopefully see some good gains in torque, but will the stock 9.5:1 be the best overall?? I'm having some trouble working out dynamic c/r on boosted engines.

I'll be using a CGA3 top feed fuel rail with 292cc SR20 injectors. Plan's to remove the washers inside the stock FPR to make it flow more and add a 8:1 FMU. I'll need an adjustable FPR to set the fuel pressure while off boost, and I can also tweak the airflow over the MAF or add a 5th injector if I need more adjustment on boost.

Just had Frank build the majority of the exhaust system. It's s/s 57mm bore, side exit. I just need a silencer and a tip. Will probably keep the stock peashooter-backbox on too for some foolery.

It's a 1 litre facelift. I focused on aesthetics the first year I owned it, lowered on coilovers and put it on 13x7 re-drilled Ford Capri Brooklands.

I managed to get the 0-60mph in about 10seconds from the 1.0 with cg13 cams and a ga16 airbox, but daily driving was still sluggish, hence why I'm now turbocharging it.

Now sporting some widened steelies:

And raised it a fair bit for a more subtle look:

The turbo is a Garret T2 from a Fiesta RS. And the manifold's built by Frank. I've been putting it together and mocking it up on a spare cg13 which will replace the 1.0 when I get time or get bored. I've got oil lines and sump almost done, throttle body and MAF are in the making.

The plan is, to be honest, very similar to franks ghetto build. For me it's a learning experience working with turbos on a budget. I also rate these 1.0 litres, so it would be fun to see what they can do. I won't be chasing figures, just experimenting and having fun too.

The head was completely stripped and cleaned. Widened and polished the ports myself, matched the inlet manifold and the gasket. Have also added additional valve spring washers to increase the valve spring rates, so I should be good for 8000rpm+ if I ever needed to go that high.

Before:

after:

I'm unsure whether to raise or lower the compression ratio on it though. These turbos are usually good for upto 1bar of pressure. Any more than that and they're prone to splitting seals quite early. I'll probably work it up to 10psi in time. However I'm unsure if lowering the c/r to the typical 8.5:1 will see the best increase in power and torque due to the low boost. I could raise it to 10.5:1 to hopefully see some good gains in torque, but will the stock 9.5:1 be the best overall?? I'm having some trouble working out dynamic c/r on boosted engines.

I'll be using a CGA3 top feed fuel rail with 292cc SR20 injectors. Plan's to remove the washers inside the stock FPR to make it flow more and add a 8:1 FMU. I'll need an adjustable FPR to set the fuel pressure while off boost, and I can also tweak the airflow over the MAF or add a 5th injector if I need more adjustment on boost.

Just had Frank build the majority of the exhaust system. It's s/s 57mm bore, side exit. I just need a silencer and a tip. Will probably keep the stock peashooter-backbox on too for some foolery.