jabran200

Ex. Club Member

Allright thought I might as well get a blog started since I am going to be making a major chnage to the micra soon(ish).

Lets start off with the pictures as I got it, the scrapes etc were done by the previous which really let it down but will be sorted soon as I have a new bumper and wing ready to go once I get them spray them sprayed and colour code the car.

I did decided to paint tthe steels BMW grey though as they were rusted up and looked nasty.

I also have some wolfrace wheels 15" which are currently waiting to be sprayed bronze with a hint of pearl (need to get my brother to spray them this weekend hopefully).

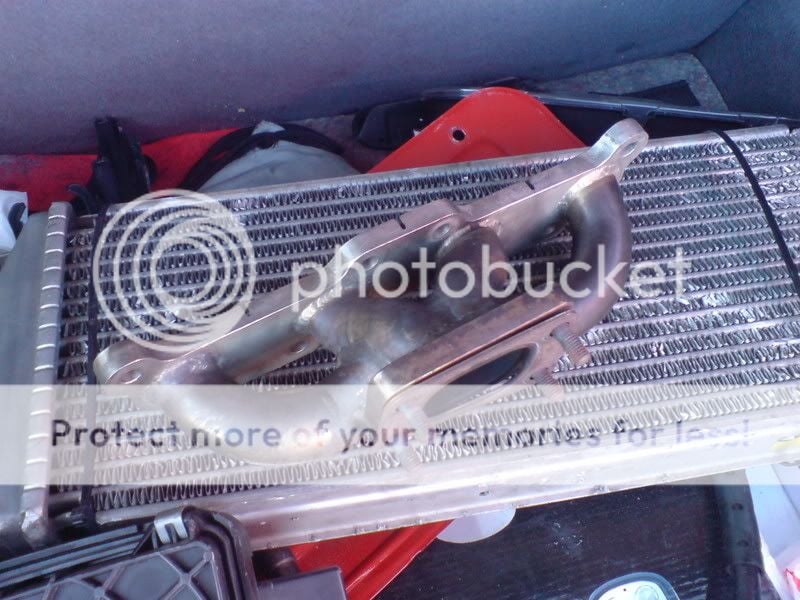

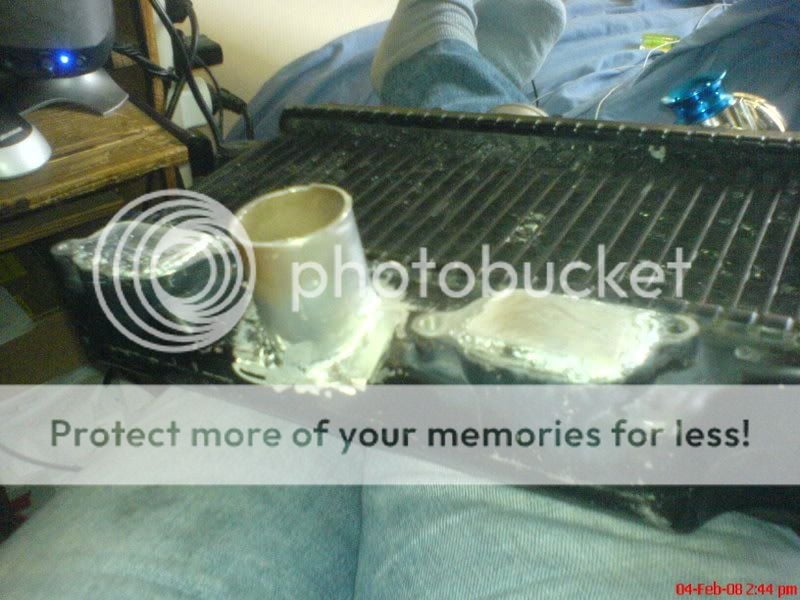

Now onto the main thing and the reason why I started the bog is because after much thought and consideration I have decided to turbo the car and thanks to Davey C on here for the manifold and to Ed for helping remove the turbo from the manifold as me and Dave could not do it lol. Loved Daves Integra on the way to Ed's, the car is absolutely mint and very nice ride.

So far I have obtained for the turbo kit:

T25 turbo with oil lines

Manifold

1.6 primera fuel rail

Front mount intercooler

Field fuel controller

sandwhich plate with oil pressure and temp gauges with senders

Whats left as of today:

Intercooler and exhaust piping (buying it from local supplier)

I think thats it can't remeber what else right now, I think i have missed a few things out but the main bits are there. Suspension and brake bits are also in process ( Pulsar brakes maybe or N15 brakes)

Will post pictures once my main PC is back online (damn motherboards fried).

If I have the piping by this sunday then I will start fabricating the piping for the intercooler this sunday if I get time.

Thanks for looking and comments and advice welcome.

Lets start off with the pictures as I got it, the scrapes etc were done by the previous which really let it down but will be sorted soon as I have a new bumper and wing ready to go once I get them spray them sprayed and colour code the car.

I did decided to paint tthe steels BMW grey though as they were rusted up and looked nasty.

I also have some wolfrace wheels 15" which are currently waiting to be sprayed bronze with a hint of pearl (need to get my brother to spray them this weekend hopefully).

Now onto the main thing and the reason why I started the bog is because after much thought and consideration I have decided to turbo the car and thanks to Davey C on here for the manifold and to Ed for helping remove the turbo from the manifold as me and Dave could not do it lol. Loved Daves Integra on the way to Ed's, the car is absolutely mint and very nice ride.

So far I have obtained for the turbo kit:

T25 turbo with oil lines

Manifold

1.6 primera fuel rail

Front mount intercooler

Field fuel controller

sandwhich plate with oil pressure and temp gauges with senders

Whats left as of today:

Intercooler and exhaust piping (buying it from local supplier)

I think thats it can't remeber what else right now, I think i have missed a few things out but the main bits are there. Suspension and brake bits are also in process ( Pulsar brakes maybe or N15 brakes)

Will post pictures once my main PC is back online (damn motherboards fried).

If I have the piping by this sunday then I will start fabricating the piping for the intercooler this sunday if I get time.

Thanks for looking and comments and advice welcome.