hi

3 quick topics

1.

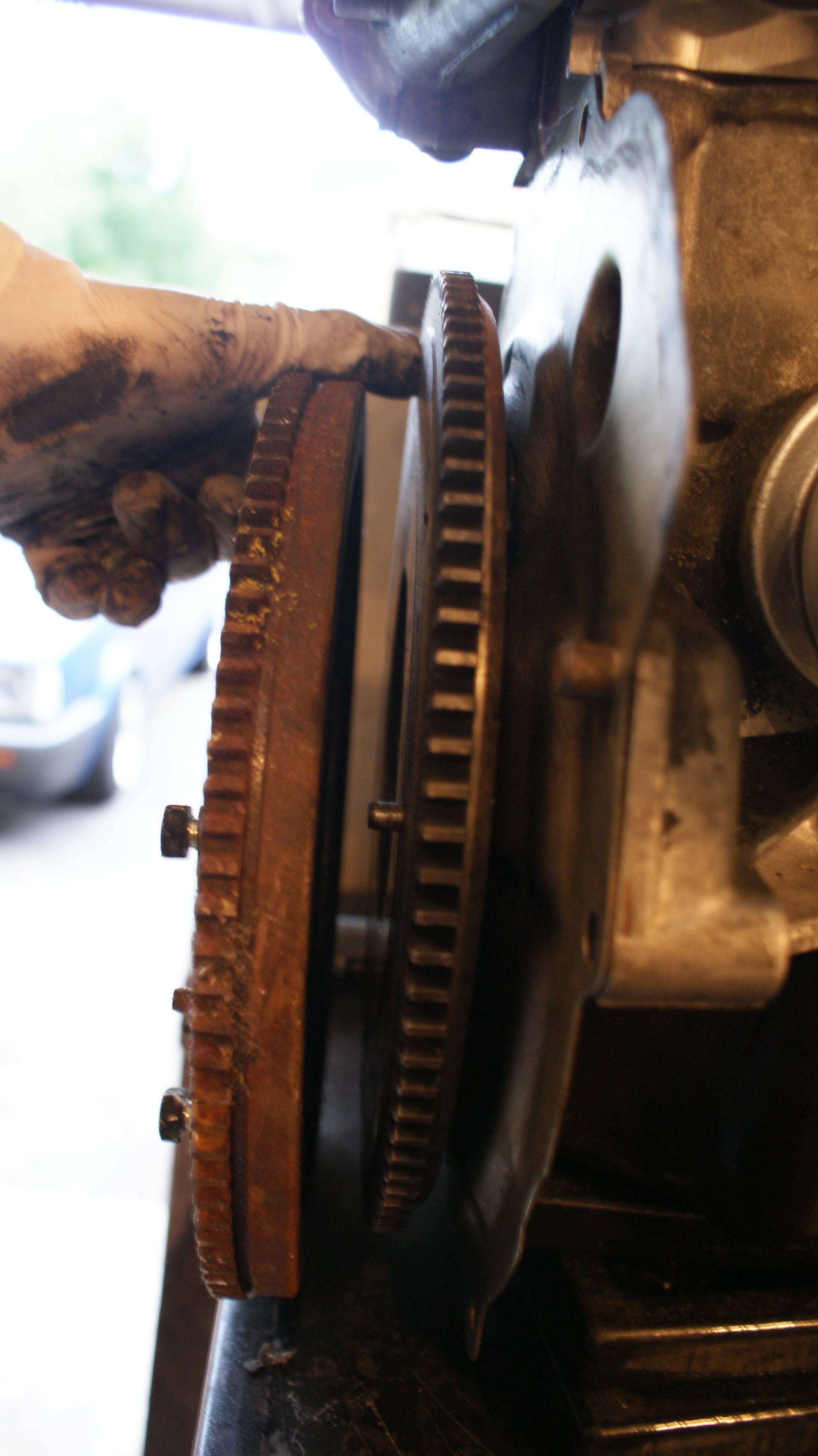

i have a lathe , which i do skim tractor flywheels on so i cant see why i couldn't lighten my own, just wondering is there any dangers to it? for the engine? and how much should i take off within reason of keeping it safe? is it a big job for an inexpierenced person to remove and refit the flywheel? i get a bit nervous about doing damage with all this stuff lol !

2.

fuel guage hasnt worked since i had the car, i know where to get at the unit underneath the back seats, but one screw comes up and the other is just spinning around, any idea's?

3.

iv just done the timing belt myself , and after starting up i noticed as soon as you start the car the temp guage takes about 4 seconds to get to full temperature, not sure if it was like this before quite possible, whats most likely wrong with it?

thanks for your time

P

3 quick topics

1.

i have a lathe , which i do skim tractor flywheels on so i cant see why i couldn't lighten my own, just wondering is there any dangers to it? for the engine? and how much should i take off within reason of keeping it safe? is it a big job for an inexpierenced person to remove and refit the flywheel? i get a bit nervous about doing damage with all this stuff lol !

2.

fuel guage hasnt worked since i had the car, i know where to get at the unit underneath the back seats, but one screw comes up and the other is just spinning around, any idea's?

3.

iv just done the timing belt myself , and after starting up i noticed as soon as you start the car the temp guage takes about 4 seconds to get to full temperature, not sure if it was like this before quite possible, whats most likely wrong with it?

thanks for your time

P