-

Please only use these forums for blogs, they are not a discussion forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dattosan Machi Suzuki twincam 4wd project pg22

- Thread starter Machi san

- Start date

Tonight Iam gonna make a start on the new engine.

Hoping to take off all the ancillaries that aren't needed. The new enginr has inlet and exhaust assemblies fitted so that'll need removing also.

If I have time before dark ill get the head off also. Is there any tips or tricks I should know before I get stuck in? I have never dealt with ohc timing chain engines before! On A-series and cambelted stuffs.

Once its broken down into components ill be able to carry bits too work for quicker progression

Hoping to take off all the ancillaries that aren't needed. The new enginr has inlet and exhaust assemblies fitted so that'll need removing also.

If I have time before dark ill get the head off also. Is there any tips or tricks I should know before I get stuck in? I have never dealt with ohc timing chain engines before! On A-series and cambelted stuffs.

Once its broken down into components ill be able to carry bits too work for quicker progression

Found this thread, appears to have the info I need

http://www.micra.org.uk/threads/42291-Cylinder-Head-removal-problem

http://www.micra.org.uk/threads/42291-Cylinder-Head-removal-problem

On my lunch break today I decided to go and make a start on the new engine.

I managed to remove exhaust manifold, dizzy, loom, power steering, rocker cover, alternator and bracket.

Tonight I may get the head off! Depends how quick it gets dark

Then I took the alternator bracket and rocker cover too work with me. I started to machine the alt bracket too make it lighter a' la Frank stylee

Also machining the writing off of the rocker cover

I managed to remove exhaust manifold, dizzy, loom, power steering, rocker cover, alternator and bracket.

Tonight I may get the head off! Depends how quick it gets dark

Then I took the alternator bracket and rocker cover too work with me. I started to machine the alt bracket too make it lighter a' la Frank stylee

Also machining the writing off of the rocker cover

Machi san;493890 Also machining the writing off of the rocker cover :)[/QUOTE said:should have left the san on it :grinning:

3 hours because I started at work but decided it would be quicker to do it with an angle grinder

grinder love

http://www.micra.org.uk/threads/47235-Grrrrinder-pics-up

naa i enquired bout it 3 hrs ago

:grinning: these guys are good at this, i am good at some stuff too, i just cant tell you any at the minute nothings coming to mind

very nice work there kev (Y) you goim turbo lad or was that early plans?

:grinning: these guys are good at this, i am good at some stuff too, i just cant tell you any at the minute nothings coming to mind

:grinning: these guys are good at this, i am good at some stuff too, i just cant tell you any at the minute nothings coming to mind

lol :laugh:

Bet your chuffed with that

Nicely done (Y) bet you can squeeze a bit more out of it :laugh:

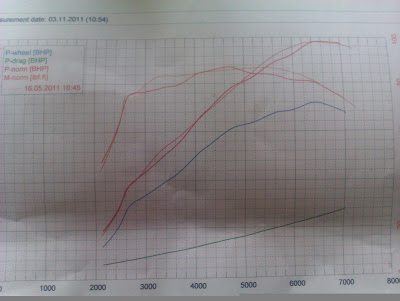

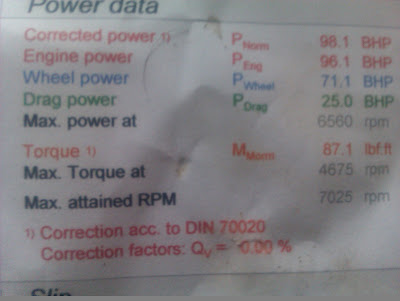

Cheers chaps, yeah really pleased with it.

I would have got a decent increase in power if I had a adjustable fuel regulator fitted. I'll go back there again once the new engine is built and fitted. Then I can get fuel pressure set up at the same time.

Steve the tuna was happy. progress! he said

Can't wait for more

your the man kev (Y) closely matched to a 4 barrel/double twinchoke webber setup mate

quads next eh :grinning:

Webers are over rated don't you think

Hi comp, cams, he

ad work, new inlet with plenum and a "more calculated" exhaust manifold. That's the current plan kev is the inconsistent curve due to the fuelling problems?

Dunno tbh, frank might know!

not bad results at all there kev not far off cracking the 100hp mark (Y) if you do away with your current manifold let us know cause i will buy it if you want to sell. i got a feeling im not gonna hear off daniel now about the mani i was ment to get off him. bloody paid him for it as well grr

Yeah no worries mate and thanks

https://www.youtube.com/watch?v=2zM9luOABsU&feature=youtube_gdata_player

https://www.youtube.com/watch?v=2zM9luOABsU&feature=youtube_gdata_player

Gearbox just threw its guts out all over the a38

Seriously need a reliable motor, was supposed to be going to collect an sr head with hks cams this afternoon

Hopefully I can have a new box fitted by tomorrow

you said it wasnt happy dint ya?

I think the diff died  and then the clutch friction plate blew up and mangled the cover plate. I don't think there is any holes in the box. The bits that come out on the road, were bits of clutch lol.

and then the clutch friction plate blew up and mangled the cover plate. I don't think there is any holes in the box. The bits that come out on the road, were bits of clutch lol.

I was cruising at 60-70 on dual carriage way. Car started to slow quickly, kinda like when the engine dies.

The speedo stopped working.

I put the clutch in and there's was an almighty crunch, then bang. Then car started free wheeling as norm.

Couldn't move gearstick, solid in gear.

Once we stopped i selected a gear and brought clutch upto bite point, i could feel clutch biting but know drive.

Then all of a sudden lost bite from clutch and could let clutch right out with no drive or stalling!

New clutch is fitted, just need to investigate the gearbox and maybe go get another from the scrapyard!

I was cruising at 60-70 on dual carriage way. Car started to slow quickly, kinda like when the engine dies.

The speedo stopped working.

I put the clutch in and there's was an almighty crunch, then bang. Then car started free wheeling as norm.

Couldn't move gearstick, solid in gear.

Once we stopped i selected a gear and brought clutch upto bite point, i could feel clutch biting but know drive.

Then all of a sudden lost bite from clutch and could let clutch right out with no drive or stalling!

New clutch is fitted, just need to investigate the gearbox and maybe go get another from the scrapyard!

you said it wasnt happy dint ya?

Yes I feel stupid because I should have bought and fitted a new gearbox and clutch by now :l

Cars basically fixed now. Just gotta put battery tray and battery in, radiator and water, bottom balljoint and tighten all the gear linkage up

Double diaphragm clutch appears to work awesome. Bite feels a little vague/soft I was expecting it too bite aggressively but it may just need a few miles to bed in a little. Couldnt test for slip cose just wheel spins on the painted garage floor lol.

Should be back together after tea

Double diaphragm clutch appears to work awesome. Bite feels a little vague/soft I was expecting it too bite aggressively but it may just need a few miles to bed in a little. Couldnt test for slip cose just wheel spins on the painted garage floor lol.

Should be back together after tea

Bit of an update.

I finished bolting the car together but when i drove home i had severe slip in 2nd gear or higher.

Reason for this was the drive plate that I had machined back by 2.4mm, well there is 3 boss that have the drive straps riveted on to mount the plate into the cover. The rivets where touching the flywheel as the clutch started to clamp.

To fix this I simply took the spare drive plate and machined the 2.4mm from the opposite side.

Now it works fine and I tested it by driving 170mile round trip to collect a sr20 ported head with hks cams.

All good

However Iam no closer to having the new engine ready

I finished bolting the car together but when i drove home i had severe slip in 2nd gear or higher.

Reason for this was the drive plate that I had machined back by 2.4mm, well there is 3 boss that have the drive straps riveted on to mount the plate into the cover. The rivets where touching the flywheel as the clutch started to clamp.

To fix this I simply took the spare drive plate and machined the 2.4mm from the opposite side.

Now it works fine and I tested it by driving 170mile round trip to collect a sr20 ported head with hks cams.

All good

However Iam no closer to having the new engine ready