I was going to stick the bike up in the "into cycling" thread, but as I'm not actually that much of a cyclist I thought I'd put it here. The rest is some other tat that i've cobbled together over the years.

BMX Based Chopper, layed back stem tube, extended rear stays, home made sissybar.

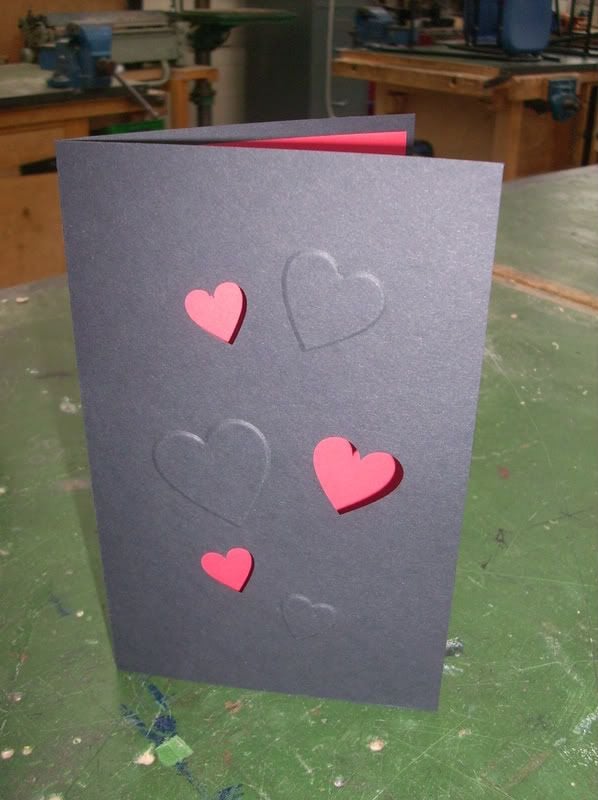

Embossded valentines card

Laser cut 1mm acrylic sheet for the press tool, which was used after the had been laser cut.

Laser Cut MDF memory stick case.

Lego brick memory stick case.

Jump Hour clock, laser cut MDF case.

Five note Keyboard and Stylophone, 555 osscilator circuit, laser cut acrylic case.

Trophies for Retro-Rides Gathering 2008.

3D CAD model of Mardave V12 RC car.

IR Remote controlled 1:24 Scale '64 Impala Lowreider. Custom PICAXE Programmable integrated circuit board with IR inputs and servo output, laser cut acrylic chassis.

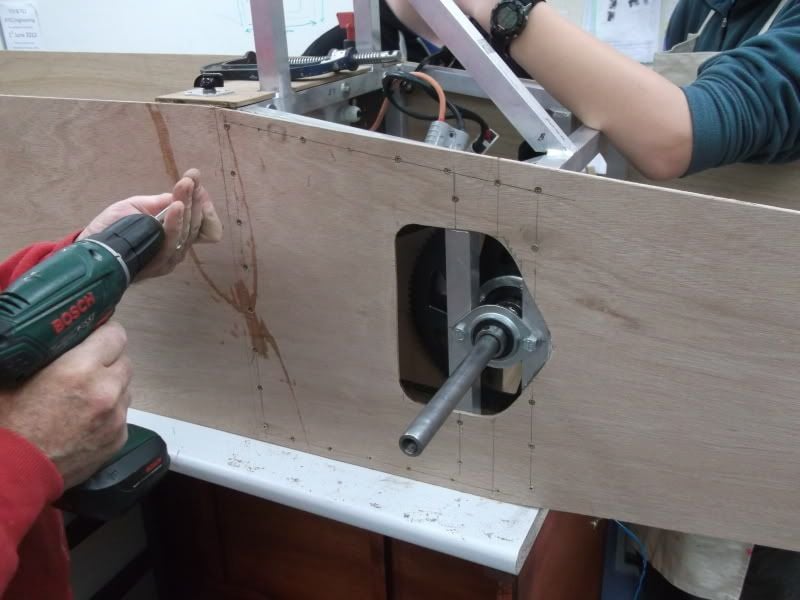

Laser cut acrylic chassis, as an example of what might be achieved for the 4x4 in schools challenge.

PICAXE PIC Scalextric lap counting and timer setup, uni project.

Pop Art Hand Bag, as an example of how resistant materials can be used in textiles.

Chess Set, laser cut acrylic and CNC turned bases. Another Uni project.

Candle Stick, acrylic and turned aluminium.

Earringings, aluminium tube with layered then laser cut acrylic inserts, laser cut acrylic case.

My Website, very basic, written in HTML in note pad. I really need to have another look at this.

www.easypcd.co.uk

EasyPCD's, laser cut acrylic PCD checking tool.

Thats everything I can find in my Photo Bucket. You might have notice how the laser cutter is without doubt my favourite toy!

What have you made when you are not messing about with cars?

BMX Based Chopper, layed back stem tube, extended rear stays, home made sissybar.

Embossded valentines card

Laser cut 1mm acrylic sheet for the press tool, which was used after the had been laser cut.

Laser Cut MDF memory stick case.

Lego brick memory stick case.

Jump Hour clock, laser cut MDF case.

Five note Keyboard and Stylophone, 555 osscilator circuit, laser cut acrylic case.

Trophies for Retro-Rides Gathering 2008.

3D CAD model of Mardave V12 RC car.

IR Remote controlled 1:24 Scale '64 Impala Lowreider. Custom PICAXE Programmable integrated circuit board with IR inputs and servo output, laser cut acrylic chassis.

Laser cut acrylic chassis, as an example of what might be achieved for the 4x4 in schools challenge.

PICAXE PIC Scalextric lap counting and timer setup, uni project.

Pop Art Hand Bag, as an example of how resistant materials can be used in textiles.

Chess Set, laser cut acrylic and CNC turned bases. Another Uni project.

Candle Stick, acrylic and turned aluminium.

Earringings, aluminium tube with layered then laser cut acrylic inserts, laser cut acrylic case.

My Website, very basic, written in HTML in note pad. I really need to have another look at this.

www.easypcd.co.uk

EasyPCD's, laser cut acrylic PCD checking tool.

Thats everything I can find in my Photo Bucket. You might have notice how the laser cutter is without doubt my favourite toy!

What have you made when you are not messing about with cars?