I have done this in the past a few times on various cars.

I have attempted twice on the K10, and both times after setting and running the car, it sounds like 'a skeleton having a w*nk in a biscuit tin'. Rechecking the clearances shows that some are out by 5mm - 10mm. Obviously, this is well over the 0.25 on the inlet and 0.30mm on the exhaust sides.

I'm getting TDC on cylinder 1 by gauging the the height of the piston with a screwdriver carefully slotted in the spark plug hole, and also by the cut out on the crank pulley to the '0' degree marking. Also getting TDC on cylinder 4 by rotating the crank 180 degrees to the opposite of TDC on #1 (and also doing the screwdriver trick).

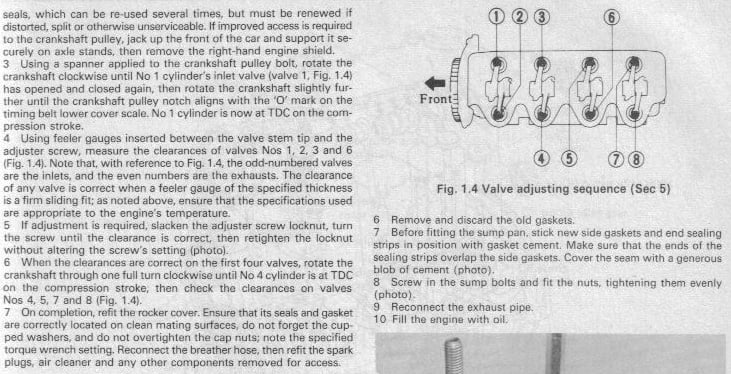

I'm not sure how this is possible, and I reckon I'm doing something wrong, and maybe following a setup diagram that is incorrect.

Does anyone have a diagram that is correct or any instructions? Thanks.

I have attempted twice on the K10, and both times after setting and running the car, it sounds like 'a skeleton having a w*nk in a biscuit tin'. Rechecking the clearances shows that some are out by 5mm - 10mm. Obviously, this is well over the 0.25 on the inlet and 0.30mm on the exhaust sides.

I'm getting TDC on cylinder 1 by gauging the the height of the piston with a screwdriver carefully slotted in the spark plug hole, and also by the cut out on the crank pulley to the '0' degree marking. Also getting TDC on cylinder 4 by rotating the crank 180 degrees to the opposite of TDC on #1 (and also doing the screwdriver trick).

I'm not sure how this is possible, and I reckon I'm doing something wrong, and maybe following a setup diagram that is incorrect.

Does anyone have a diagram that is correct or any instructions? Thanks.