pietro

Ex. Club Member

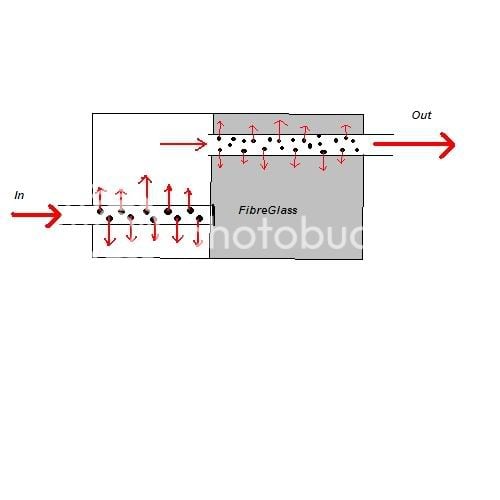

Just wondering as I have heard that reverse flow mufflers have merely 60 - 70 percent the flow of a straight-through muffler?

Photo: http://us1.webpublications.com.au/static/images/articles/i14/1474_3lo.jpg

Also is it possible to drill the exhaust (with a massive drill piece) through the exit pipe to the entrance pipe to create a channel for better flow on the cheap?

Photo: http://us1.webpublications.com.au/static/images/articles/i14/1474_3lo.jpg

Also is it possible to drill the exhaust (with a massive drill piece) through the exit pipe to the entrance pipe to create a channel for better flow on the cheap?