SirChris

Educated Bodger

Haha made myself look like a right pleb here Paul. I just would of thought cheap alloy ones would strip threads.

Haha made myself look like a right pleb here Paul. I just would of thought cheap alloy ones would strip threads.

But what ahhh. So alloy ones are weaker but Paul's running them. I wanted to buy some so I think I worrying about going round a corner and the wheels come off haha. So what still confused sorry guys.

Ohhhh I get it now. I have never really had alloys. I never knew you had different bolts. Good job I now know lol. Ta for explaining lol.no lets clarify chris:

wheel nuts made from steel that's used for alloy wheels (think their taper angle differs from wheel nuts used for pressed steel wheels) are stronger, safer, cheaper

wheel nuts made from alu alloy or other exotic materials that's used for alloy wheels might be a bit lighter but are too expensive, easier to cross thread during fitting and torquing.

alot of disadvantages outweighing the irrelevant benefits

Jesus I am a nob. Sorry for clogging your thread Paul haha. Am I usually this special?

NiceStandard fare I'd say.

Ball bearings need to be packed with grease, all wd40 will do is flush what little grease there is left in it out and accelerate wear. If it's a sealed bearing then just replace the bearing.k tonight its been squealing constantly warm or cold, needs fixing.

sprayed wd40 behind the waterpump pulley, no change.

sprayed wd40 on the tensioner pulley axle, gets quiet briefly but then few yards down the road to squeals again.

so removed the pulley and oiled the bearing with thin wd40 rather than thick engine oil, reassembled.

its running alot quieter but can still hear a very faint amount driving through the streets.

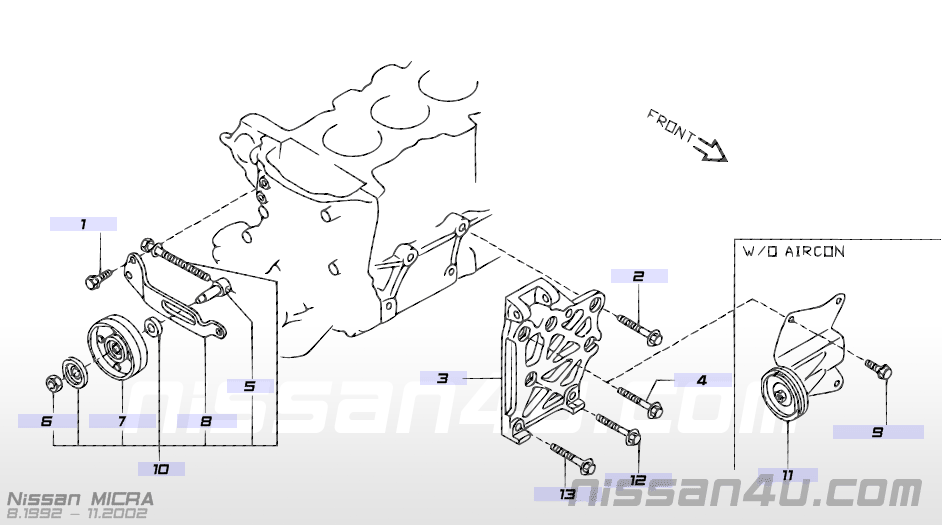

I think both belt tensioners actually need replacing

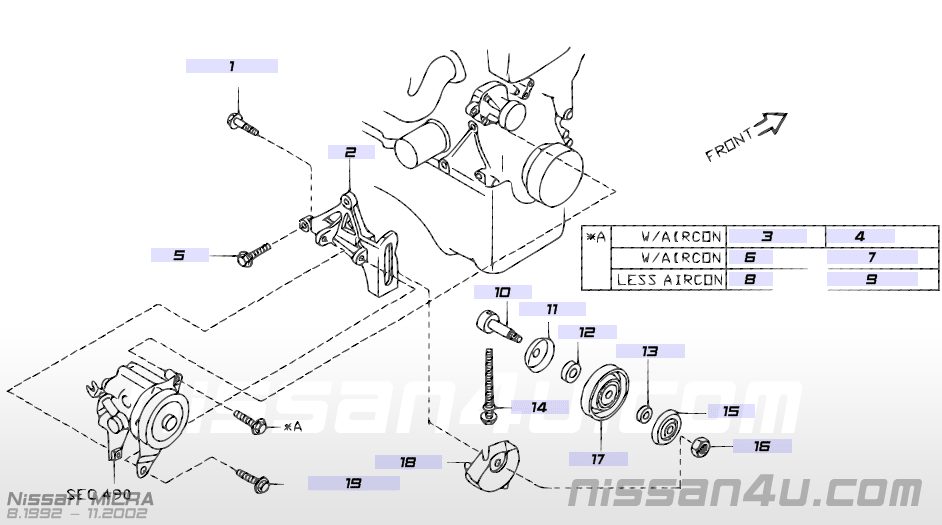

You won't need SKF bearings, they're so expensive because they are made to ridiculously tight tolerances for CNC machines and the like, the bigger one even have a little laser engraving to mark the point of maximum eccentricity!so here's an auxilary belt idler pulley

first grind off the 2 rivet lips on both sides that is holding the pulley together

then split the pulley apart

push the bearing out the other cap

the bearing is an SKF 6301 2RS1

37x12x12mm

took the alternator idler off to check if that uses the same bearing too

the pulley

that uses a NSK 6301DULX

and appears to be exactly the same

so I need two 6301 rubber sealed deep groove ball bearings

looked at simplybearings.co.uk and they have a budget 63012RS for £2.69ex vat

9.7kN dynamic load, 4.2kN static load, 20k rpm in grease

http://simplybearings.co.uk/shop/p1...ove+Ball+Bearing+12x37x12mm/product_info.html

they also have the genuine SKF 6301 2RS1 for a whopping £25.68ex vat!

but only handles 8.19kN dynamic, 4.05kN static, 14k rpm. why would I buy this one?

http://simplybearings.co.uk/shop/p1...ove+Ball+Bearing+12x37x12mm/product_info.html

was thinking of getting it at the local bearing shop tomorrow at lunch but don't have the time to drive around tbh so gonna reassemble these pulleys and order a pair of budget bearings to be delivered soon and then just replace em.

£8.26 for two bearings delivered, not bad compared to £30-60 for one friggin pulley from anywhere else.

If wd40 quietened it slightly then is def the bearings surely?

nice work woth the bearingstrange that it still makes noise. you dont have powersteering? as i dont see it in the pics, mine squeeked at bit once but after greasing it, it was gone too. hmm water pump is a mess to get out when the engine is still in.

Simple check. Pop the PAS belt off if you can

Intro

Hey everyone

I’m Paul and here’s a story bout the journey with my micra.

It starts with a 1998 k11 1.3 slx that’s been with the family since new. It had NATS, electric windows, body coloured bumpers & wings, 13” nissan primera alloys, airbag, abs, adjustable headlight angle, rear wiper, sunroof and PAS.

My sister had it for few more years until in 2006 she needed something bigger and with less faults cos it was drinking fuel, misfiring, uneconomical repair bills etc. She had an eye on a ford focus but the garage said they’ll only give £200 part exchange for the micra.

Now, I’ve had me licence since 2003 and have yet to get my first car. Upon hearing bout her quote I thought I couldn’t just let the oppurtunity go since I know the cars history, would be cheap to run and was great to drive cos I learnt to drive in it in 2003 between driving lessons when it was me sisters. £200 sounded like a bargain so I agreed to buy it.

Hi Polly, quick question. I'm trying to fix/clean out my idle control valve and been told you knew the setting on datascan to get it to open up so I can clean it without manually dismantling it and making a faff? Any help you can offer is appreciated

Jesus Paul... Can you remember writing this? How many posts laterand the original car

Ah well that's my idea out the windowunless u mean fit a non-PAS belt & tensioner to just run the water pump and eliminate the PAS end? which I can't do cos I don't have any.

Ah well that's my idea out the window

Cant hurt to have a new water pump anyway

Thanks Pollyif you have any diagnostic software that can temporarily override the IACV like datascan, imo you should first clean and free up the valve mechanism and then calibrate the IACV with datascan so it's physically shut when the value says zero.

I've updated my guide here to include cleaning and adjusting the IACV.

http://micra.org.uk/threads/pollymobiles-rebuild.35251/page-19#post-446256