You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nissan Micra K11 SR+T

- Thread starter Stani1029

- Start date

Stani1029

Club Member

Begun to strip the almera of all that we thought was needed including the full interior loom

Regarding the loom we removed it carefully and marked any wires we might possibly forget then cable tied it all together for safe storage, this will later be unpicked or all unwanted wires and rewired to suit lights etc

Regarding the loom we removed it carefully and marked any wires we might possibly forget then cable tied it all together for safe storage, this will later be unpicked or all unwanted wires and rewired to suit lights etc

Stani1029

Club Member

The engine is now sitting on all its mounts! Next i had to remove the engine and fully seam weld the mounts to the body, add some extra plates to the rear and gearbox mounts to strengthen them

Done!

Rear mount just needs plated each side

Gearbox mount needs a couple plates at the other side where its been trimmed to fit. A closer look you can see some new welds (once finished ill take better photos out the car)

Bonus Pic

Done!

Rear mount just needs plated each side

Gearbox mount needs a couple plates at the other side where its been trimmed to fit. A closer look you can see some new welds (once finished ill take better photos out the car)

Bonus Pic

Stani1029

Club Member

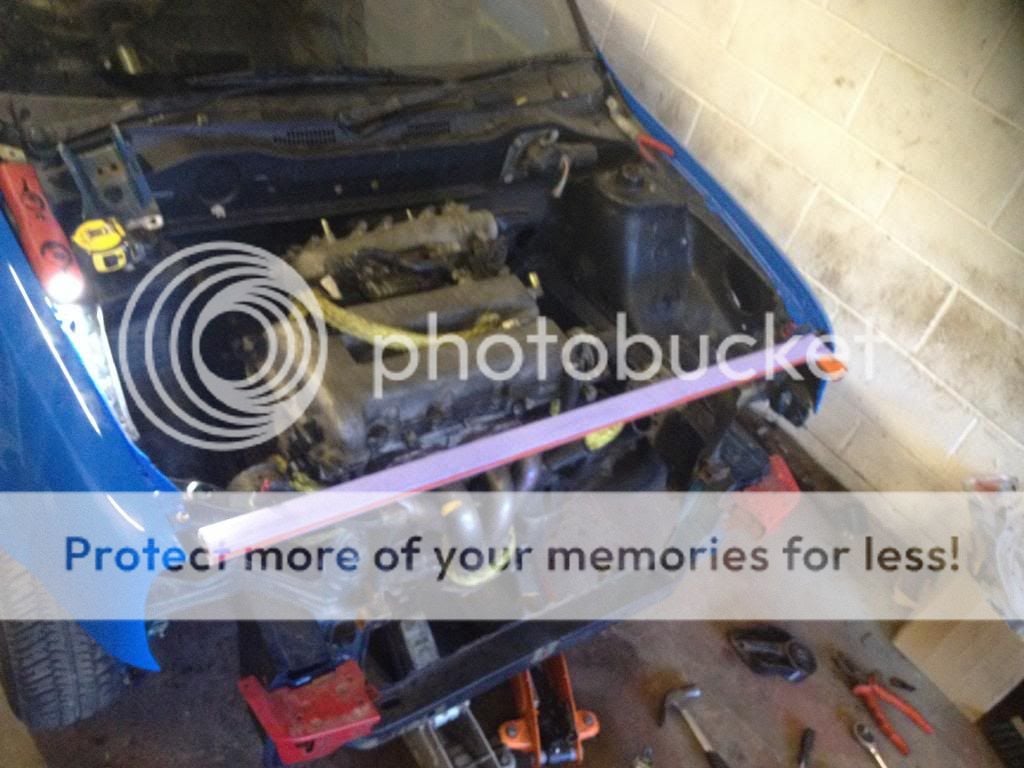

All engine mount are completely welded up and had 2 coats zinc primer. Engines back in and it isnt half a fiddle now that the bulky gearbox mount is in the way!

Now a 2.0ltr engine bay

Centre member been plated either side

Gearbox mount fully welded and plated, also put 2 bolts into it as a precaution

Altenator bracket adjusted to give about 10mm clearance

Now a 2.0ltr engine bay

Centre member been plated either side

Gearbox mount fully welded and plated, also put 2 bolts into it as a precaution

Altenator bracket adjusted to give about 10mm clearance

Stani1029

Club Member

We have gears and a clutch!  both the stabiliser and gear selector bars bolted on, but the gear selector was a little too short so needed lengthened.

both the stabiliser and gear selector bars bolted on, but the gear selector was a little too short so needed lengthened.

Micra left v Almera right

So cut off the micra one near to the end and cut the almera one with plenty (measured that it needs extended 15mm) so bolted upto car and marked up.

How i held the gearstick in the neutral position

Done

Now onto the clutch. bracket that holds the pedal was removed so welded one from the donor on

Had to strip the full dash out the donor car then drill the spotwelds to get this stupid little bracket lol so pedal now secure, clutch cable on but i still dont think its right!

You can see in the pic above ive redrilled another notch in the arm further down. It just doesnt seem to pull the arm back enough. Turns out i should have used the almera clutch cable and complete bracket instead of chopping and welding a piece of the micra.

So bought what was needed

Micra left v Almera right

So cut off the micra one near to the end and cut the almera one with plenty (measured that it needs extended 15mm) so bolted upto car and marked up.

How i held the gearstick in the neutral position

Done

Now onto the clutch. bracket that holds the pedal was removed so welded one from the donor on

Had to strip the full dash out the donor car then drill the spotwelds to get this stupid little bracket lol so pedal now secure, clutch cable on but i still dont think its right!

You can see in the pic above ive redrilled another notch in the arm further down. It just doesnt seem to pull the arm back enough. Turns out i should have used the almera clutch cable and complete bracket instead of chopping and welding a piece of the micra.

So bought what was needed

Stani1029

Club Member

Stani1029

Club Member

Next was to get the hubs pressed out but the guy i would use i couldnt get a hold of so a little facebook beg and i picked up this from a mate

6 tonne press

Now to figure out how to mount the hubs for pressing, well since im a joiner that didnt take long

And now were here

What i need to do is have the almera hub (where the cv bolts into) machined down to press fit into the micra wheel bearing/cast housing. The OD of the hub measures 38mm and the bearing measures 35mm so 3mm to be machined off and some machining to the cv's and i can move onto driveshafts!!

6 tonne press

Now to figure out how to mount the hubs for pressing, well since im a joiner that didnt take long

And now were here

What i need to do is have the almera hub (where the cv bolts into) machined down to press fit into the micra wheel bearing/cast housing. The OD of the hub measures 38mm and the bearing measures 35mm so 3mm to be machined off and some machining to the cv's and i can move onto driveshafts!!

Stani1029

Club Member

Got my mate to machine the cv joints for me, You can see the size difference

Micra cv

Almera cv

In action shot

Hubs fitted, and driveshafts stripped down and trimmed to fit and tacked together

One thing to note, you cant get almera gti cv joints that work. I bought a set but they didnt fit the almera driveshaft but luckily tried my mates pulsar driveshafts and the fronts fitted perfectly! So took them off his hands and used the outer parts for my mock shafts. (Outer front pulsar shaft welded to inner almera)

Last thing i need to do before i order shafts is to fit some wheel studs into the hubs so i can set the car on its wheels and make sure the driveshafts dont bottom out on the inner cv. Im already confident its correct as ive raised the hub up more than enough and theres still plenty clearance!

Micra cv

Almera cv

In action shot

Hubs fitted, and driveshafts stripped down and trimmed to fit and tacked together

One thing to note, you cant get almera gti cv joints that work. I bought a set but they didnt fit the almera driveshaft but luckily tried my mates pulsar driveshafts and the fronts fitted perfectly! So took them off his hands and used the outer parts for my mock shafts. (Outer front pulsar shaft welded to inner almera)

Last thing i need to do before i order shafts is to fit some wheel studs into the hubs so i can set the car on its wheels and make sure the driveshafts dont bottom out on the inner cv. Im already confident its correct as ive raised the hub up more than enough and theres still plenty clearance!

Stani1029

Club Member

Wheel studs in and car o n its wheels. Shafts are spot on, plenty travel left inwards and not too close to the edge of the inner cv's so welded them up and will hand them in to be made

ZzzZzzZzzZzz

Not a great deal difference in shaft length!

Now i know its getting closer to a test drive ive started fitting loom and tidying up some engine bits, there is a few parts i need so hope to pick them up whilst im awaiting the driveshafts

Cheers

ZzzZzzZzzZzz

Not a great deal difference in shaft length!

Now i know its getting closer to a test drive ive started fitting loom and tidying up some engine bits, there is a few parts i need so hope to pick them up whilst im awaiting the driveshafts

Cheers

Stani1029

Club Member

Even more loom removed lol not much more can be removed from what i can see!

Got the majority of it wired in now, from what i can think theres only the reg plate lighting, front wiper, and horns to do. I also would like to adjust the front section of loom so that it doesnt cross along the front end of the car. Hoping to get away with not extending all the wires but it looks a little close length wise, will find out soon enough!

Taking shape, need some more electrical tape and cable ties and that will tidy it off

Got the majority of it wired in now, from what i can think theres only the reg plate lighting, front wiper, and horns to do. I also would like to adjust the front section of loom so that it doesnt cross along the front end of the car. Hoping to get away with not extending all the wires but it looks a little close length wise, will find out soon enough!

Taking shape, need some more electrical tape and cable ties and that will tidy it off

Stani1029

Club Member

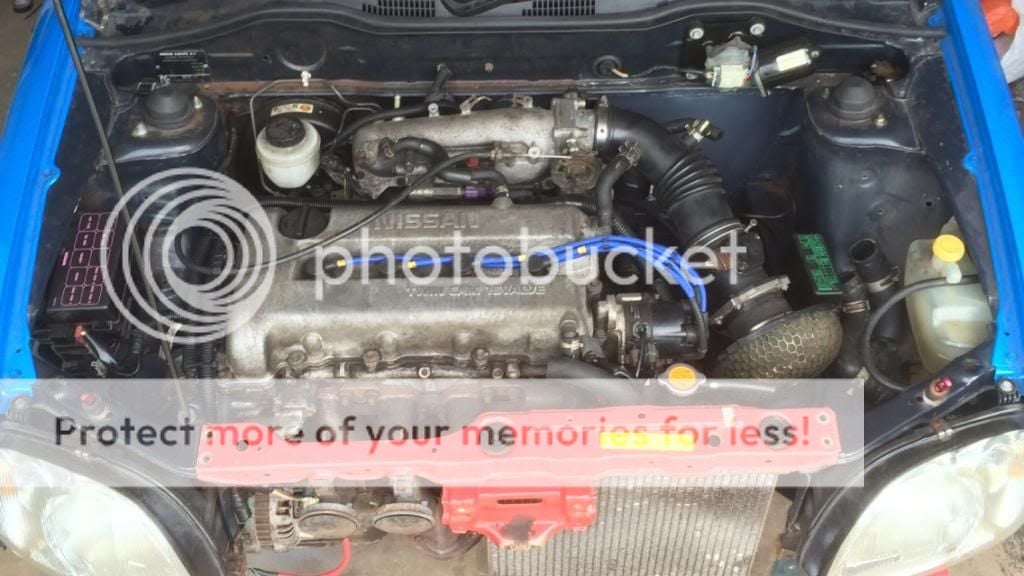

Beautiful!

Thought i would get the driveshafts put together last night but one of the boots i had was a little too big so will need to source one that will fit a bit better. Also those clamps that need crimped are a pain in the ass!! Basically wasted all the ones i had so will order more along with the proper crimp tool. Took about 20 mins to get the inner joint out the passenger side of the gearbox!! Heres as far as i got with the shafts LOL

Got my bucket seat fitted, only needed minor welding to fit it to the micra rail and ive just fitted a normal seatbelt at the moment.

Spoiler fitted

And lastly was a good few hours with the loom which normally runs along the almera slam panel. Ive rerouted it, pulled wires back and extended a few to get it in this position and im over the moon with how it looks! All wrapped in split pipe and taped up

The green fuse box to the right of the engine bay will be mounted there and the power lead from that will be extended into the car to meet the main battery connection as im mounting the battery below the half dash on top of the exhaust tunnel.

Cheers

Thought i would get the driveshafts put together last night but one of the boots i had was a little too big so will need to source one that will fit a bit better. Also those clamps that need crimped are a pain in the ass!! Basically wasted all the ones i had so will order more along with the proper crimp tool. Took about 20 mins to get the inner joint out the passenger side of the gearbox!! Heres as far as i got with the shafts LOL

Got my bucket seat fitted, only needed minor welding to fit it to the micra rail and ive just fitted a normal seatbelt at the moment.

Spoiler fitted

And lastly was a good few hours with the loom which normally runs along the almera slam panel. Ive rerouted it, pulled wires back and extended a few to get it in this position and im over the moon with how it looks! All wrapped in split pipe and taped up

The green fuse box to the right of the engine bay will be mounted there and the power lead from that will be extended into the car to meet the main battery connection as im mounting the battery below the half dash on top of the exhaust tunnel.

Cheers

Stani1029

Club Member

Nice!!

Shafts look great......pricey?

Sent from my iPhone using Tapatalk

They were £600 total, about what i expected

Great job. Looks good.

Sent from my Nexus 5X using Tapatalk

Sent from my Nexus 5X using Tapatalk

Out of interest what grade of steel are the new drive shafts made from? Seem to remember that when I was snapping drive shafts on my tuned MG Midget only EN39B ones were strong enough to take the torque..........They were £600 total, about what i expected

Stani1029

Club Member

Out of interest what grade of steel are the new drive shafts made from? Seem to remember that when I was snapping drive shafts on my tuned MG Midget only EN39B ones were strong enough to take the torque..........

Im not sure i didnt bother asking to be honest

Stani1029

Club Member

that rolling blue shell was all the way back in 2013??

damn how did all those yrs go by?

loving this blog update, nice one stani

Sure is paul, you have a good memory! The years have certainky flew past! I have plenty more to add to this.

Just doing so as i find time

I hope that wasn't a very expensive mistake,.....Im not sure i didnt bother asking to be honest

Last edited:

Stani1029

Club Member

I hope that wasn't a very expensive mistake,.....Did you make the company that manufactured them aware of the power and torque that you are expecting to put through them? The original shafts were almost certainly cold forged and heat treated, not turned from bar stock.

Everytime i hand over cash i hope its not a mistake. And i explained to them what they were for and my hp aim. If they break then tough crap for me lol

Stani1029

Club Member

Got a clutch bracket and cable through, was a total PITA to bolt up to the bulkhead but got there. Clutch feels good so another job out the way. I also tidied all the interior loom taping it where seen and fixing it in place with cable tie clips. Battery has been repositioned (welded the tray in) and extended the power lead from the fusebox. Sort of made a bracket for the fusebox so its a bit neater too. Grabbed the slam panel and radiator from the donor micra and put it in place to see fitment etc and measure for bits. Will need a slimline fan for sure! And lastly nearly finished the brake pipes just a few more clips and 1 flare to go and i can fill it up

Stani1029

Club Member

Stani1029

Club Member

Well i hope i never have to replace the water pump belt with engine in car, what a mission! Had to remove the engine mount and lower the engine and remove the crank pulley!

But got the belts on and tight, got gearbox oil in, coolant is in so i decide to give the engine a turn over for first time turned over well and sounded ok.

turned over well and sounded ok.

Received my panhard rod too but couldnt get it fitted

And heres the exhaust ill use at the moment

But got the belts on and tight, got gearbox oil in, coolant is in so i decide to give the engine a turn over for first time

Received my panhard rod too but couldnt get it fitted

And heres the exhaust ill use at the moment

Stani1029

Club Member

Got the panhard rod sorted out! Stub had been removed and replaced with a nut and bolt but was no use to me as the bolt was too small in diameter.

You can see ive also fitted the fuel tank in the above pic. Also got the fuel lines in, filter, petrol. So maybe its time to start??!!!!

All set

But then....

Heres what happened

Turns out theres a hole in the oil filter and its in a really awkward place so ive no idea how it got there New filter ordered, also need a new battery so hopefully next video will be it driving as i couldnt get the chance!!!

New filter ordered, also need a new battery so hopefully next video will be it driving as i couldnt get the chance!!!

So glad the NATS worked!

Cheers

You can see ive also fitted the fuel tank in the above pic. Also got the fuel lines in, filter, petrol. So maybe its time to start??!!!!

All set

But then....

Heres what happened

Turns out theres a hole in the oil filter and its in a really awkward place so ive no idea how it got there

So glad the NATS worked!

Cheers

Stani1029

Club Member

Ive had a very busy last few weeks but i got a few hours tonight and its done! New oil and filter, new battery, new track rods, bumpers on, new reg plates, all bolts checked over....

Phone died not long after so no videos of the drive but all is well! Didnt quite open the taps as much is id like to but better safe than sorry. Car has surprised me more than id expected, the pickup at low speed is just awesome, feeling really excited about whats to come with the car!

Little 0-75mph vid

AND NOW time to take it apart again haha!

Phone died not long after so no videos of the drive but all is well! Didnt quite open the taps as much is id like to but better safe than sorry. Car has surprised me more than id expected, the pickup at low speed is just awesome, feeling really excited about whats to come with the car!

Little 0-75mph vid

AND NOW time to take it apart again haha!

Stani1029

Club Member

Head has been skimmed, and also 2 exhaust studs have been helicoiled. Ive fitted new studs, valves cleaned up and ground in. Need to extend my valve spring compressor to fit around the head before i can re-assemble.

Block is also handed in for hone and skim so will pick that up next week which will give me plenty to so once ordered the last parts from nissan

Block is also handed in for hone and skim so will pick that up next week which will give me plenty to so once ordered the last parts from nissan

Stani1029

Club Member

Picked up my crank seals from nissan and worked in the freezing cold garage to get some more done, heres where im at...

Cosworth 1.1 gasket and studs. Arp conrod bolts and nissan piston rings/valve stem seals. Also time for the s14 pistons and rods to be fitted

Was going to put my head studs in but there full of metal so will need to clean it all out first.

Cosworth 1.1 gasket and studs. Arp conrod bolts and nissan piston rings/valve stem seals. Also time for the s14 pistons and rods to be fitted

Was going to put my head studs in but there full of metal so will need to clean it all out first.

Similar threads

- Replies

- 25

- Views

- 23K

- Replies

- 26

- Views

- 5K