I can't be alone in thinking that a little extra performance could be squeezed out of the non 1.6 or diesel engined cars if the engine could breath better.

Not wanting mind numbing induction roar I steered away from open air filters, (though in hindsight, what I have finally come up with could be useful in that application as well), so the initial stage was to buy a K&N panel filter to replace the standard paper one.

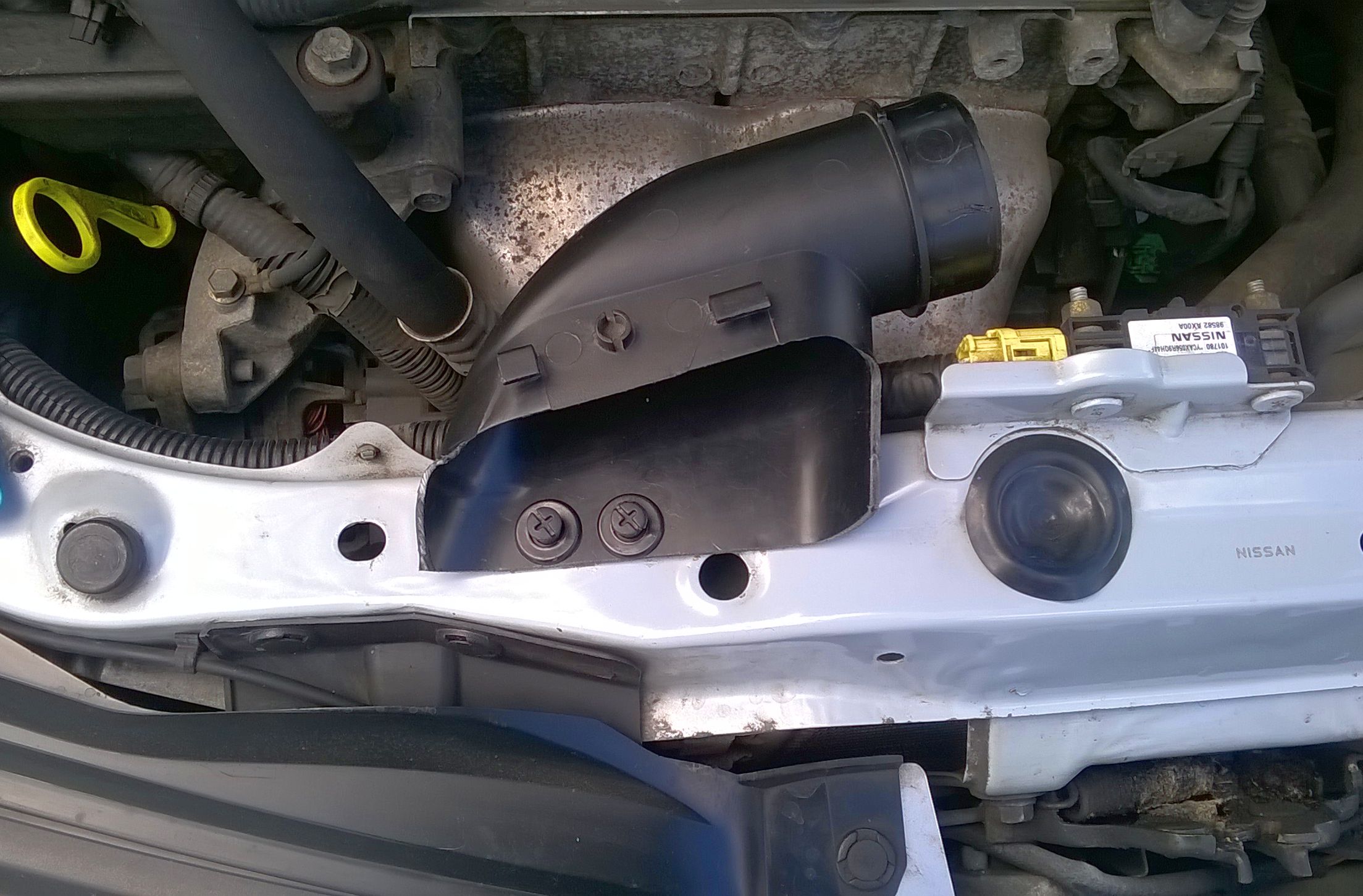

The next thing I wanted to do was find a way of neatly replacing the, apparently very restrictive, air feed from the slam panel, with a resonant chamber in it, with something considerably more free flowing.

I had a look at the air feed box under the filter and soon realised that there was two variations (both with yet another resonant chamber 'stuck' on the side.

The one on my car was the post 2005 design:-

Resonant chamber integral with the box:-

The inlet spigot fouled up with support webs for the chamber on the side :-

:-

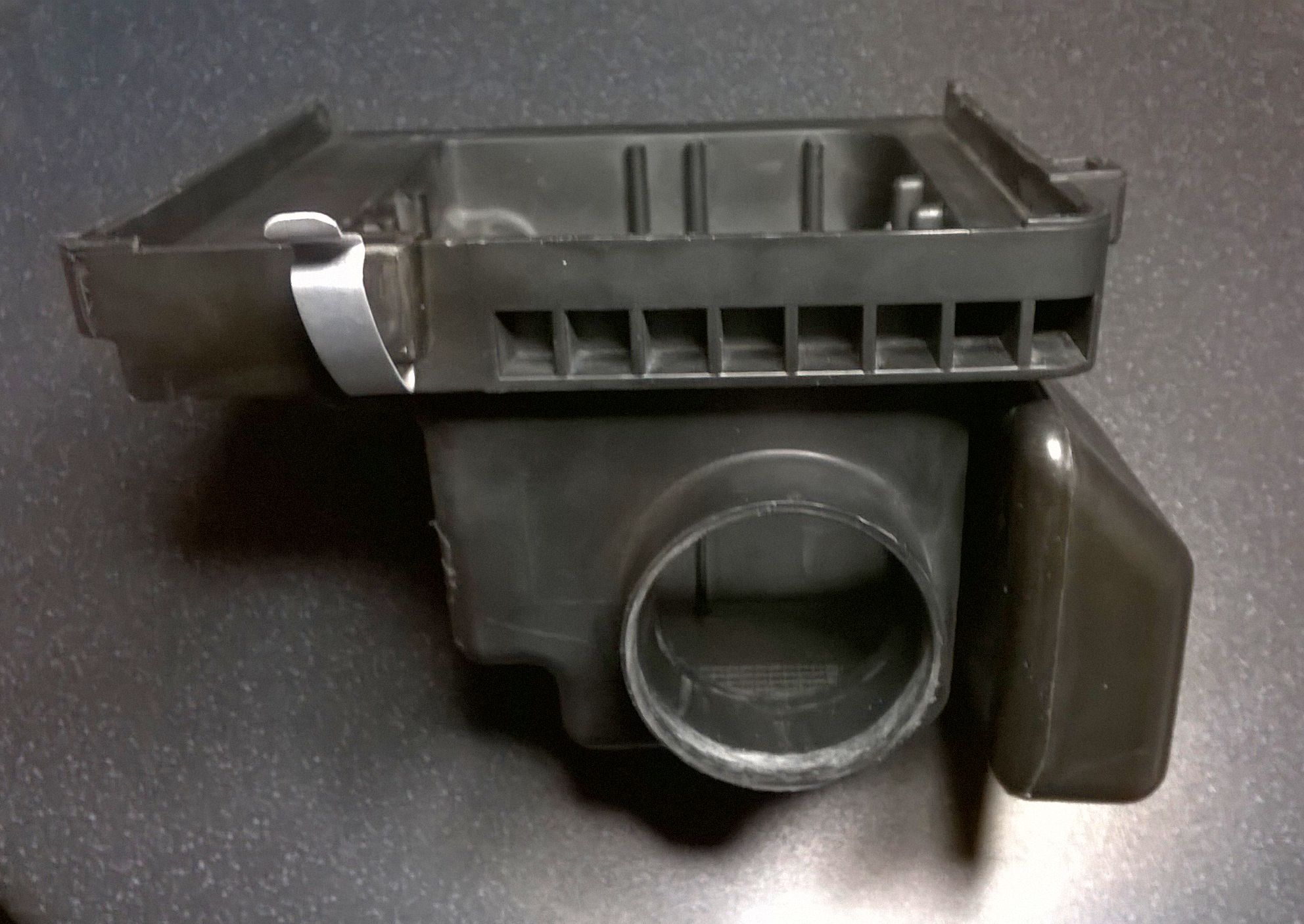

The earlier version had a separate chamber attached to the side of the box with rivets:-

And with a usable inlet spigot

With this in mind I decided that the earlier version would be better to 'play with' and I managed to buy a complete early type engine top cover/ filter box on ebay, for the princely sum of £14.50 inc carriage, with the bonus that it came with a spare MAP sensor and vacuum switch and piping still attached

Having got the replacement earlier filter box to play with, I measured up the spigot, finding that the O/D was a just under 55mm and the bore tapered from 50mm at the opening to about 46mm on the inside edge.

I plan to open this up to a consistent 50/51mm to maximise flow.

The next stage was to design a suitable 'big bore' cold air feed that looked as if it was OEM

More to follow tomorrow.......

.

Not wanting mind numbing induction roar I steered away from open air filters, (though in hindsight, what I have finally come up with could be useful in that application as well), so the initial stage was to buy a K&N panel filter to replace the standard paper one.

The next thing I wanted to do was find a way of neatly replacing the, apparently very restrictive, air feed from the slam panel, with a resonant chamber in it, with something considerably more free flowing.

I had a look at the air feed box under the filter and soon realised that there was two variations (both with yet another resonant chamber 'stuck' on the side.

The one on my car was the post 2005 design:-

Resonant chamber integral with the box:-

The inlet spigot fouled up with support webs for the chamber on the side

The earlier version had a separate chamber attached to the side of the box with rivets:-

And with a usable inlet spigot

With this in mind I decided that the earlier version would be better to 'play with' and I managed to buy a complete early type engine top cover/ filter box on ebay, for the princely sum of £14.50 inc carriage, with the bonus that it came with a spare MAP sensor and vacuum switch and piping still attached

Having got the replacement earlier filter box to play with, I measured up the spigot, finding that the O/D was a just under 55mm and the bore tapered from 50mm at the opening to about 46mm on the inside edge.

I plan to open this up to a consistent 50/51mm to maximise flow.

The next stage was to design a suitable 'big bore' cold air feed that looked as if it was OEM

More to follow tomorrow.......

.

Last edited: