Time was quickly passing and I was running out of time to get the car sorted ready for my track day. I spoke to a couple of people who work with bodywork (to get a price on cutting out and replacing the N/S/R arch) and they said it was solid metal and replacing the panel could distort the quarter panel.

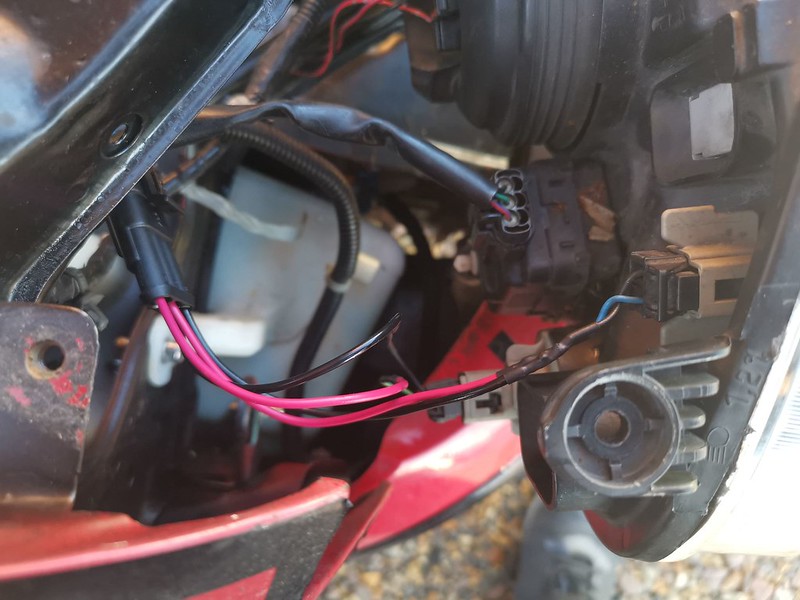

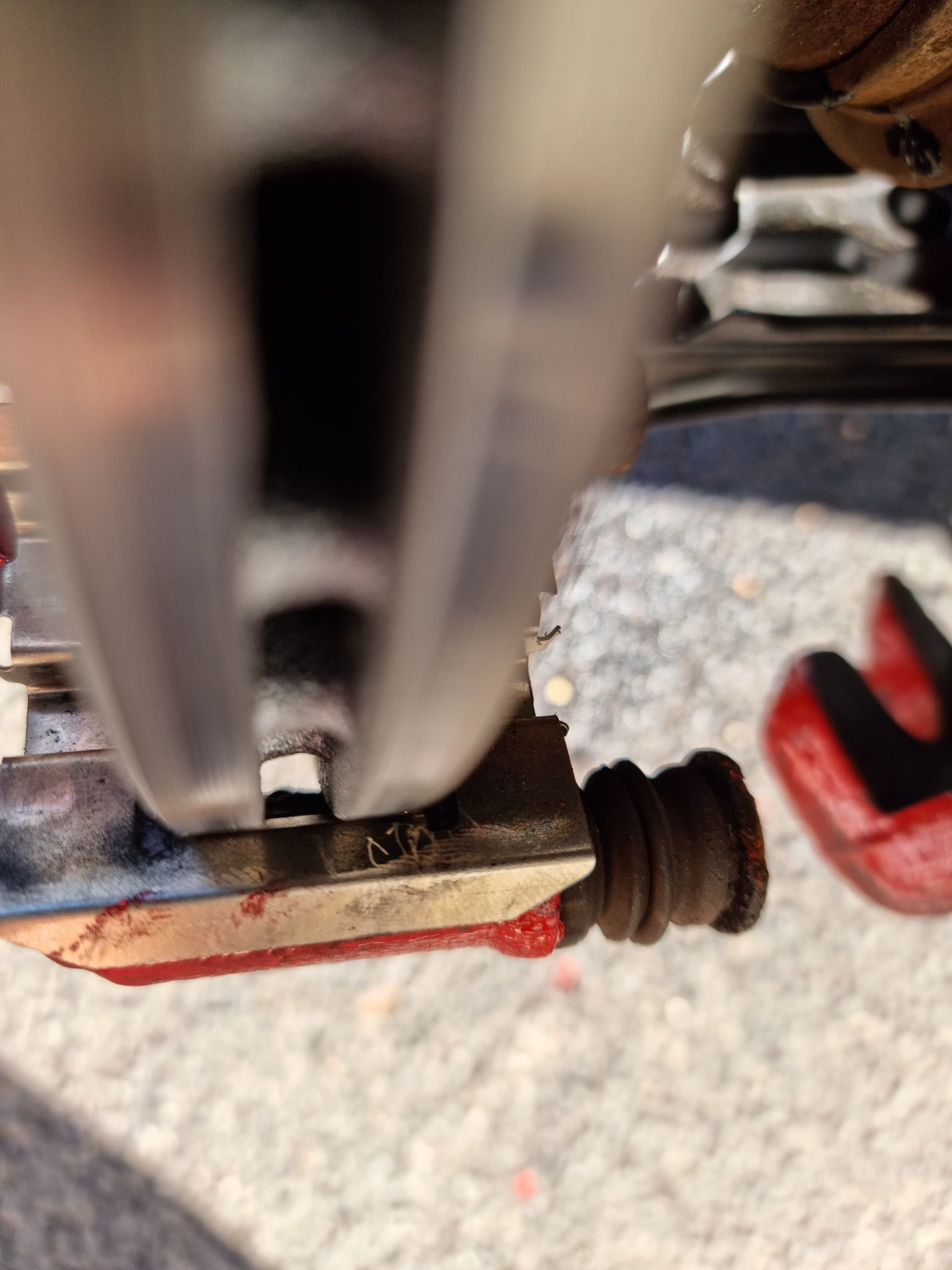

So I attacked the arches with a flap disc on a grinder to see what I was dealing with. Turns out it IS good metal underneath, winning!

Driver side wasn't as bad but had started to bubble so that received the same treatment

The areas were cleaned, rust treated and then filled. I envy those who can do body work especially filler. These areas are pretty straight forward, but it certainly tested my patience lol.

Unfortunately I dont have any final photos of the repair.

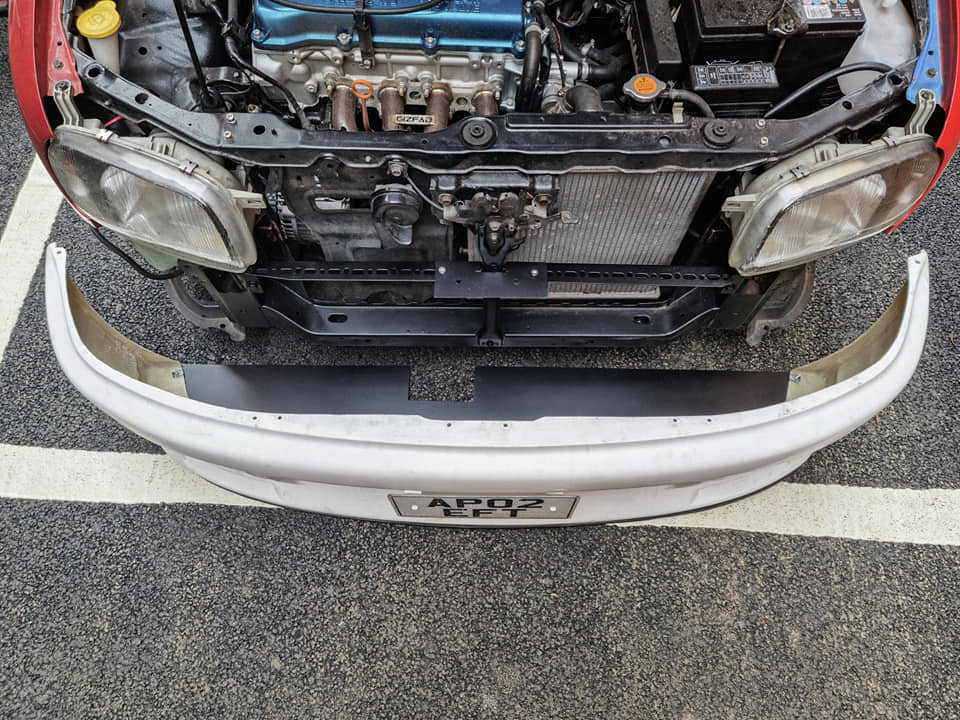

Fast forward to last sunday (27th June). A friend had kindly allowed me to use a space in his unit to prep and paint the car. The paint booth he has is currently being re-done otherwise this whole process would have been alot better and easier.

With the car prepped with 400 grade sand paper, wiped down and masked it was ready for painting. The rear bumper was left on, a replacement was purchased and was being prepped off the car (I needed to cut the bottom for the diffuser and exhaust)

We then used 8 cans of Montana Black Code Red with pink dot caps to paint the car. Someone recommended these caps as they give a wider spray pattern. We also repainted the bonnet because it was streaky from when I had painted it at home.

But we didn't stop there...

I thought it would be a great idea to PAINT a livery on. I didn't know how vinyl would stick to the graffiti paint so went this way instead.

We started off by applying 6mm 3M fine line tape

Masked off the rest of the car

We then sprayed the areas with Montana Black Snow White

A band approx 25mm was masked down the sides along with the tops of the bumpers ready for the next colour

Very happy with how crisp the lines have turned out

Next was to fine line the bonnet and spray that white

It was time for the clear coat. I applied the first coat of Satin lacquer (Montana call it Varnish). By the time I had done the whole car, I noticed it had started to go cloudy in places.

Perhaps it was too cold in the unit? So we pulled out the little heaters and see if there were any improvements

Much better!

But the bonnet was proving to be a real struggle. I tried spraying far away and up close, tried the wider nozzle and normal nozzle, tried holding a heater above and then spraying. Nothing was seeming to work....ARHH!!

In the end my friend mixed up 500ml of 2k lacquer and used his spray gun. Not ideal conditions but its the only option we had

He did a single coat/pass over the whole car, left it about 20mins and we unmasked. This was now the end of the 2nd full day and we would return the following morning.