Hi Everyone,

since there is not much info on the dig-s engine, i want to have a info/disussion thread about what we know and what we want to know. about the Engine. Maybe some of you found ot something, which will be interessting for others too.

Technical Roundup (source: wikipedia)

The HR12DDR is a 1.2 L supercharged straight-3 engine. It produces 72 kW (97 hp) and 143 N·m (105 ft·lbf).

Some of the pertinent features are:

The Supercharger

Boost

Sources/further read:

http://www.greencarcongress.com/2012/05/hr12ddr-20120530.html

http://www.nissan-global.com/EN/TECHNOLOGY/MAGAZINE/downsizing.html

http://www.sae.org/mags/sve/NEWS/9194

since there is not much info on the dig-s engine, i want to have a info/disussion thread about what we know and what we want to know. about the Engine. Maybe some of you found ot something, which will be interessting for others too.

Technical Roundup (source: wikipedia)

The HR12DDR is a 1.2 L supercharged straight-3 engine. It produces 72 kW (97 hp) and 143 N·m (105 ft·lbf).

Some of the pertinent features are:

- Compression ratio of 13:1 (see article about compression bellow)

- Continuous Variable Valve Timing Control System (CVTCS)

- Direct Injection Gasoline (DIG)

- Miller cycle

- Supercharged

- Variable capacity oil pump

- Hydrogen-free diamond like carbon(DLC) coated valve lifters and piston rings

- Sodium filled exhaust valves

- High efficiency

- 2010 Nissan Micra

- 2012 Nissan Note

- A high-compression ratio of 13:1 is quoted; however, it is really the Miller cycle’s expansion ratio that is comparable to a +9:1 compression ratio in a conventional engine.

- Bore: 78mm

- Stroke: 83.6mm

- Displacement: 1198ccm

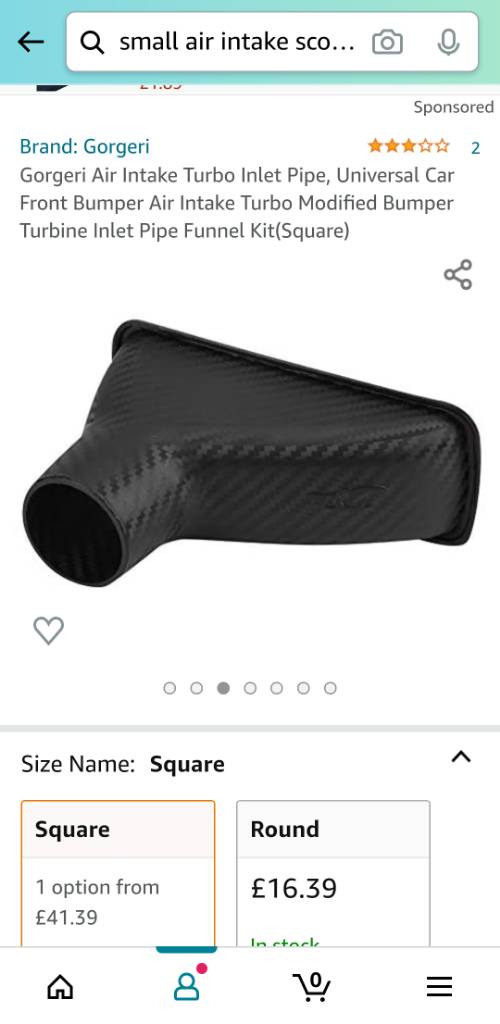

The Supercharger

- The Supercharger is an Eaton R410 [flow chart]

- Stock pulley size is: 62mm (diameter)

- Nissan used an Eaton Roots-type supercharger with twin 4-lobe rotors, with a revolution of 2.4:1 compared to engine revolution.

Although the supercharger already has low-rotating friction under a non-boosting condition, Nissan adopted the electromagnetic clutch—driven directly by the ECU—for further friction reduction.

For boost pressure control, the engine uses a bypass valve upstream of the throttle valve. - An air-cooled intercooler is downstream of the supercharger.

Nissan said that this is important to maintain knock quality using Miller cycle on the boost condition.

It also makes it easy to control the charged air volume along with recirculation under partial boost conditions.

Boost

- Fitted a Boost Gauge, before the Magnetic Purge Valve

- Pressure while driving

- ~.6bar / 8.7psi vacuum

- ~.45bar / 6.5psi boost

- the car`s top-speed is limited to 195km/h (approx: 121mp/h)

- after fitting my boost gauge, i realised that the boost is falling to ~.2bar at top speed.

- SC Pulley Calculations/Combinations

- how to override/exploid the bypass-valve, in order to achieve more boost.

- ...

Sources/further read:

http://www.greencarcongress.com/2012/05/hr12ddr-20120530.html

http://www.nissan-global.com/EN/TECHNOLOGY/MAGAZINE/downsizing.html

http://www.sae.org/mags/sve/NEWS/9194